SERVICES

Service

【Paper】Research on the Application of AUTOCERA in Biomimetic Artificial Bone Implants

Professor Wu Chengtie's team at the National Key Laboratory of High-Performance Ceramics and Ultra-Microstructure, Shanghai Institute of Ceramics, Chinese Academy of Sciences

2020Published in the journal "Science Advances" in the yearScience Advances

"3D Printing Haversian Structure Bone Scaffolds Achieve Multicellular Delivery for Bone Regeneration"

Abstract:The integration of scaffold structure and function in tissue engineering is crucial for mimicking natural bone tissue. However, the complexity of hierarchical structures, the requirements for mechanical properties, and the diversity of bone-resident cells are the main challenges in constructing biomimetic bone tissue engineering scaffolds. This paper successfully prepared Haversian biomimetic bone scaffolds with complete hierarchical Haversian bone structure using digital light processing (DLP) based 3D printing technology. By altering the parameters of the Haversian biomimetic bone structure, the compressive strength and porosity of the scaffolds can be well controlled. The Haversian bone mimetic scaffolds accelerate the growth of blood vessels and the formation of new bone in vivo through in vitro induced osteogenesis, angiogenesis, and neurogenesis differentiation, demonstrating the great potential of multicellular delivery. This work provides a new strategy for designing structured and functional biomaterials for tissue regeneration by mimicking natural complex bone tissue.

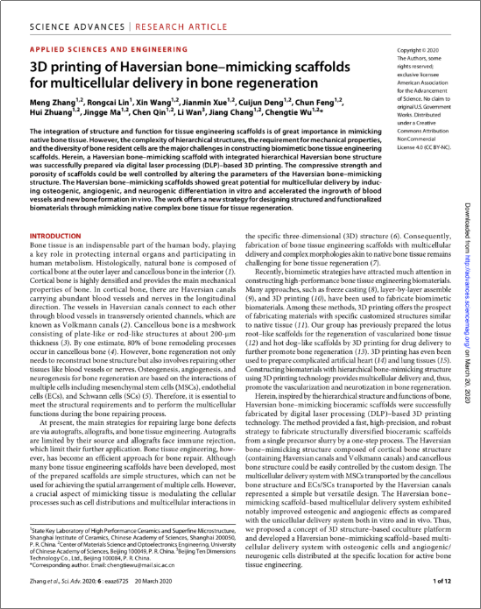

Research Mechanism: Figure 2.1 illustrates the formation of biomimetic bone scaffolds and the growth of bone and blood vessels. The 3D printed Haversian bone mimetic scaffolds combine Haversian canals, Volkmann canals, and trabecular bone structures for delivering osteoblasts and angiogenic cells. Osteoblasts are seeded in the trabecular bone structure of the scaffold, while angiogenic cells are seeded in the Haversian canals. The multicellular transport system based on the Haversian bone mimetic structure facilitates the formation of new bone and new blood vessels.

Figure 2.1 Schematic diagram of Haversian mimetic bone scaffolds, modeling, printing, growth of osteoblasts and angiogenic cells

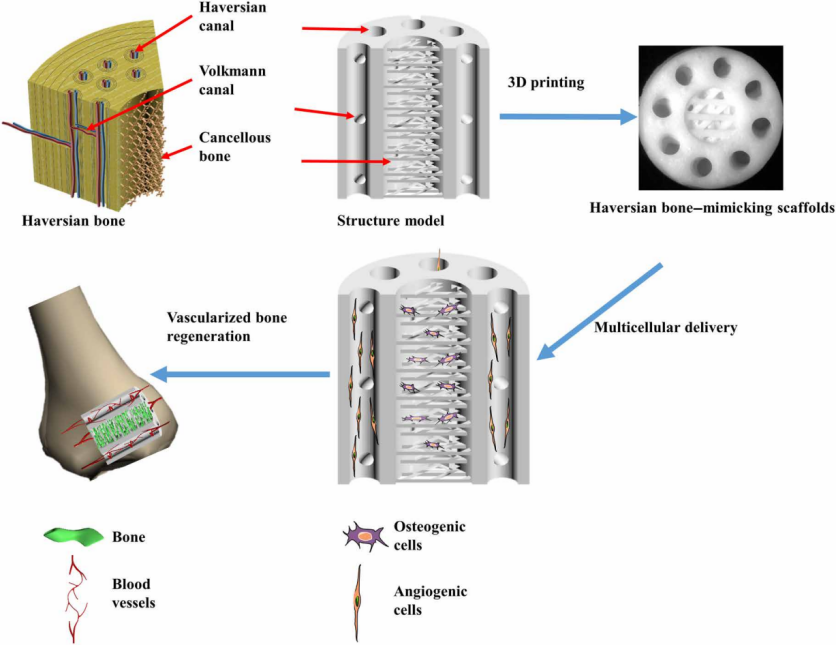

Figure 2.2 showsCortical and trabecular bone structure Haversian mimetic bioceramic scaffoldsmodels with different characteristic structural parameters. Haversian canals and Volkmann canals of different sizes and quantities.

Figure 2.2 Biomimetic bone scaffolds with different structural designs

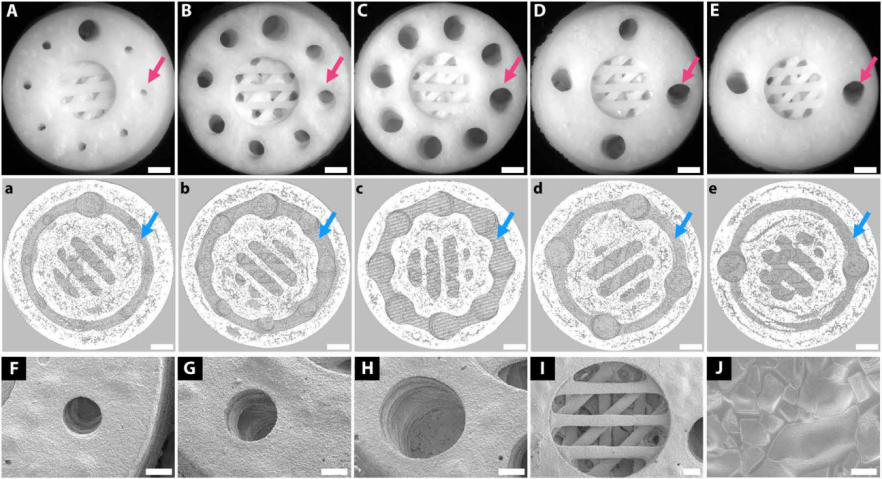

Figure 2.3 shows the performance of different scaffold structures, including compressive strength and porosity.

Figure 2.3 Compressive strength and porosity of biomimetic bone scaffolds with different structural designs (baris 400μm)

Figure 2.4 indicates that the Haversian bone mimetic bioceramic scaffold based on the RBMSC-RAEC co-culture system enhances the formation of new bone and new blood vessels in rabbit femoral defects.

Figure 2.4 The Haversian bone mimetic bioceramic scaffold based on the RBMSC-RAEC co-culture system enhances the formation of new bone and new blood vessels in rabbit femoral defects.

For biomimetic artificial bone bioceramic scaffolds, utilizing active bioceramic materials to simulate human bone structure is key. The superior forming capability of Ten Dimensions Technology's AutoCera-M comes from its high-precision, high-stability mechanical system and precisely designed optical system, as well as its flexible parameter adjustment range. In this study, the high mechanical performance of the cortical bone part and the highly refined trabecular bone part were integrated, perfectly achieving biomimetic manufacturing of human bone structure. The equipment can batch print different implant component parts with flexible adjustments in multiple structural sizes, allowing for the optimal structural parameters for multicellular delivery in bone regeneration to be obtained in further research.