Bioceramics

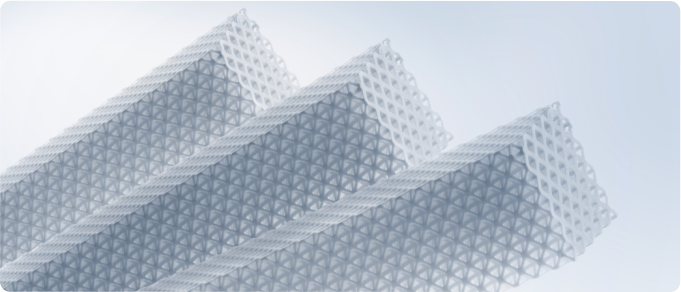

In orthopedic implants, bioceramic materials such as hydroxyapatite, tricalcium phosphate, and bioglass, with good bone conduction and bone induction properties, help the damaged bone achieve self-repair. Compared to metal implants, they eliminate the permanent presence of foreign objects, reduce postoperative risks, alleviate patient suffering, and long-term inconvenience, making them excellent medical materials.

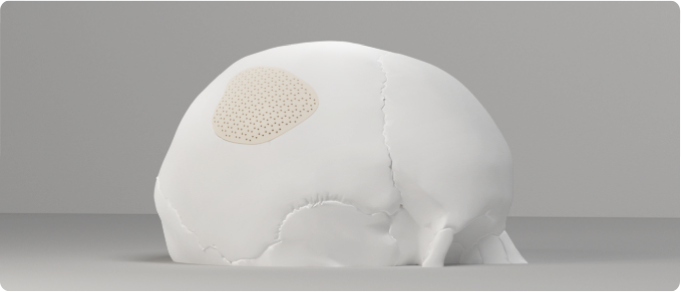

3D Printed Customized Implants

Through AUTOCERA ceramic 3D printing, the powder material is manufactured to the size of the defect area, achieving precise personalized customization, reducing the complexity of the doctor's operation, and shortening the surgery time. Specially customized bionic structures are tailored according to different defect areas and patient conditions to maximize the self-repair effect by exerting the best induction and conduction characteristics.